Description

OVERVIEW

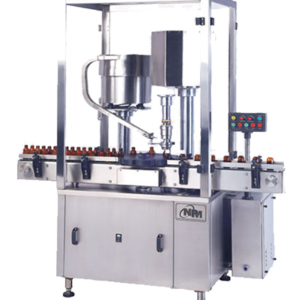

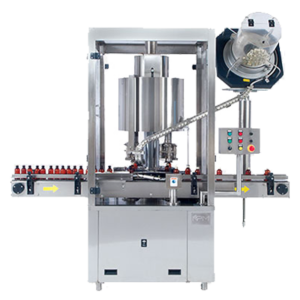

NPM’s Automatic Multi Head ROPP cum Screw Capping Machine is a multifunctional, self- sufficient machine which consists of a stainless steel leg that has a height adjustment mechanism. The machine is perfectly built on strong welded MS frame that closes entirely in stainless steels and doors that are furnished to facilitate the process. The machine bares:

ROPP Capping: The feed container is placed on the conveyor belt that is led into the in-feed star wheel with the help of an in-feed worm. The star wheel guides the container under the sealing while the bottles are placed with caps from the delivery chute. The neck and body of the container are stationed below the rotating head where the operation of threading and sealing is done.

Screw Capping: The same process of ROPP Capping is followed with single functional difference. In Screw Capping, the perfect operation takes place under the rotating head on a pre set torque.

SPECIFICATION

| Technical Specifications | |||

|---|---|---|---|

| Model | NARCS / SC – 100 | NARCS / SC – 150 | |

| Output / Hour* | 2400 to 4800 | 4800 to 6600 | |

| No. of ROPP/Screw capping heads | 4 No. each | 6 Nos. each | |

| Electrical Specification** | Main Motor | 1.5 HP / 415 Volts / 50 Hz. | |

| Cap feeder bowl | 300 watt vibratory | ||

| Direction of Movement** | Left to Right | ||

| Height of Conveyor** | 860 mm to 910 mm | ||

| Change parts required | (A) Container: Star Wheel, Center guide, Feed Worm | ||

| (B) Cap: Die, Delivery Chute, Bowl for ROPP and Chute, Bowl, Cap star plate and Chuck Jaws for screw cap | |||

SALIENT FEATURES

- No container no cap arrangement.

- No head change over as equipped with alternative heads

- S.S. elegantly matt finished body.

- Single motor synchronizes conveyor, star wheel, & platform turret.

- Adjustable height of conveyor belt, to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- Pick & Place arrangement for screw capping.

- Screw cap Torque adjustable

- Specially designed hopper is provided to increase storage capacity of bowl.

- Low noise level, low power consumptions.

- Drain tray around the machine platform.

- SS cladding or hard chrome platting of all exposed parts to ensure long life and resistance against corrosion.

- Synchronized A/C drives to synchronize Conveyor, Star wheel, Platform turret & Capping bow

- Universal coupling for quick and easy setting of In-feed worm.

- Adjustable bottle height gauge for easy and quick setting.

For more details, Please click here.