Description

OVERVIEW

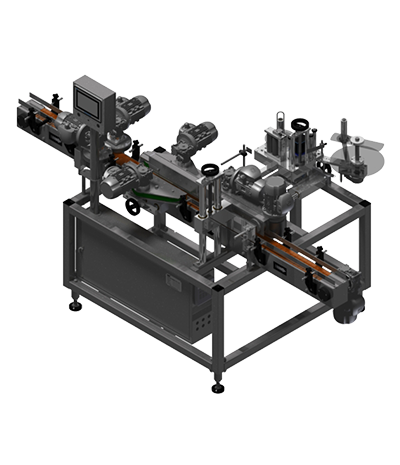

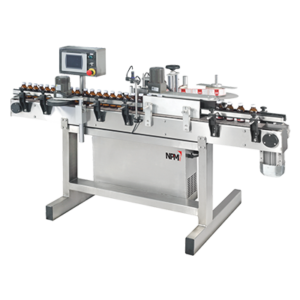

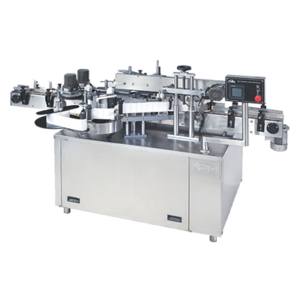

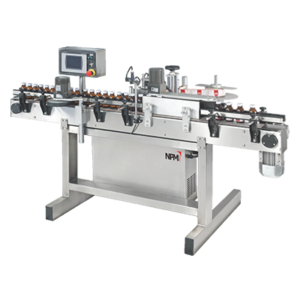

The Automatic Vertical one side flat Sticker Labeling Machine NASAL-150F is one of the most users friendly. The machine is used for one side labeling on flat surface of flat container. The containers positioned & accurate spacing between two containers by the belt spacing device and a belt drive mechanism hold the container from top of the container for one side labeling on flat container, an electronics product sensor sense container & release a label from self adhesive label roll. If machine is equipped with batch printing device in that case batch printing device prints the batch no. & other matter on label during label is stationary means time between sensing of two label. The sensed container moves on conveyor, sticker label at labeling point gets applied on labeling surface of flat container. Then the labeled container moves further through a pressing device ensures neat & perfect fixing of label.

SPECIFICATION

| Technical Specifications | ||

|---|---|---|

| Model | NASAL – 150F | |

| Direction of Movement | Left to Right | |

| Output/Hour* | 2400 to 3600 containers | |

| Electrical Specification** | Conveyor Motor | 0.50 HP, 230 Volts, 50 Hz |

| Pressing device motor | 0.25 HP, 230 Volts, 50 Hz | |

| Top Bottle Guide Belt | 90 Watt, Gear Motor | |

| Sticker Roll Stepper motor | 6V DC | |

| Height of Conveyor** | 860 mm ± 50 mm | |

| Input Specifications | ||

|---|---|---|

| Label Specification | Length** | 30 mm to 180 mm |

| Width ** | 16 mm to 100 mm | |

| Roll Diameter | Max. 300 mm X ID 75 mm | |

| Space between two label | Min. 3 mm in anti clock wise | |

| * Depending on the shape & size of container & label size. | ||

| ** We can supply as per customer requirements. | ||

SALIENT FEATURES

- Rigid MS structure with elegantly matt finished SS cladding

- Suitable for one side labeling on flat bottle.

- Container hold from top for perfect & accurate labeling.

- GMP design.

- Accurate label placement.

- Full Security Package including counter.

- Secondary pressure unit.

- PLC touch screen system.

- Product data storage facility.

- Very less down time for change over.

- Various batch code printers can be installed (optional)

- Bar code detection, missing label detection & misprinting detection can be installed with rejection (optional)

For more details, Please click here.