Description

OVERVIEW

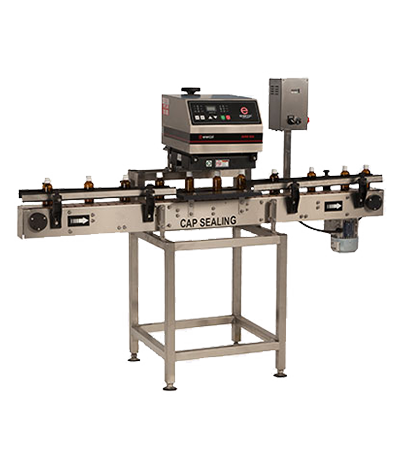

NPM’s Induction Sealing Machine is a completely waterless system that eliminates the need for water recirculation, saving floor space and money. The newest in induction sealing technology, it uses advanced power supply circuitry with the coil wound. It has specialized thin wires as minute as strands of hair which prevents heating the coils and thus, make the machinery – an innovative air-cooled sealing head machine. The advanced mechanism consumes less energy and fewer operation costs. Simple plug-in sealing head design allows changeover in minutes.

NPM has engineered a vast collection of sealing heads that meets the specific demands of a variety of package configurations and packaging operations. Our customized sealing heads and quick-change design feature smoothens the procedure of changing sealing head.

SPECIFICATION

| Technical Specifications | |

|---|---|

| Output /Minute* | Up to 200 bottles @ 100 ml |

| Seal Diameter | 20mm to 80mm |

| Control | User-friendly operator interface Microprocessor control |

| Induction Unit consisting of | – All in one Sealing head |

| – Self protective circuitry | |

| Conveyor Specification | – Length: 5 feet |

| – Width: 90mm | |

| – Height: 850 ± 50mm | |

| – SS structure | |

| – Delrin | |

| – 0.5 HP motor with ACVFD. | |

| Input Specifications | ||

|---|---|---|

| Container Size | Round Shape | Diameter: ∅ 28 mm to ∅ 60 mm |

| Respective Height : 60 mm to 120 mm | ||

| Flat / Square | Length : 30 mm to 70 mm | |

| Width : 20 mm t0 50 mm | ||

| Respectively height 58 mm X 120 mm*** (Height option for other bottle height available) | ||

| * Depends on bottle size. | ||

| ** We can supply as per customer requirements. | ||

| Utility Requirement | |

|---|---|

| Electrical supply | 3 Phase + Neutral + Earthing |

| Electrical Load | 0.5 Kw |

SALIENT FEATURES

- Air cooled system having lots of advantages over conventional water cooled system.

- Less mechanical parts, less energy consumption and zero maintenance.

- Power supply with advanced IGBT circuitry.

- Push button control panel with digital meter.

- Very Compact footprint.

- Spring mount assembly used to aid the operator in positioning the power supply over the conveyor.

- No wad Detection and rejection system (Optional)

For more details, Please click here.