Description

OVERVIEW

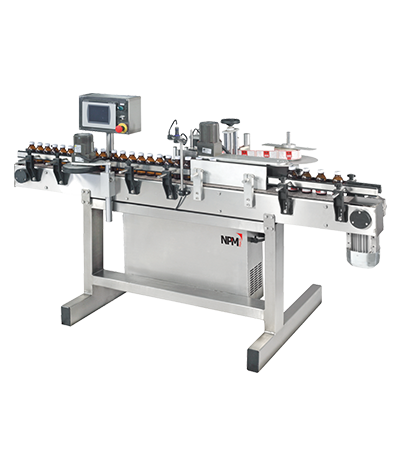

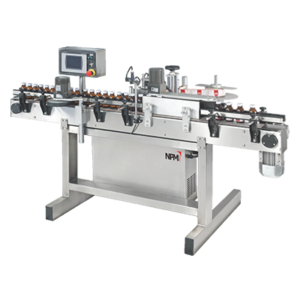

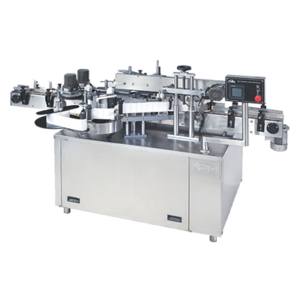

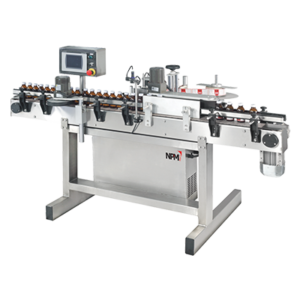

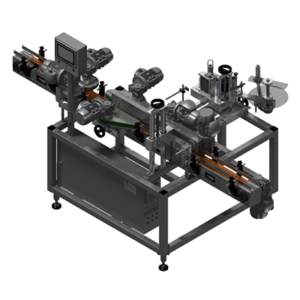

NPM’s NHL-150 is an automatic labelling machine that uses cold glue to label round container made from a variety of materials. From glass and plastic to aluminium and cardboard containers, the machine handles all labelling operations efficiently. This machine is manufactured with stainless steel and a hard chrome plating to all exposed parts and is applied to increase the machine life and increase resistance to corrosion. Such a solid build makes the NHL-150 most eligible labelling machine for your automated packaging line.

The machine comes fully equipped with adjustable settings to align with your other machines in the line. A no container- no label rule programmed into the system helps avoid wastage and aids in keeping the machine neat and clean. Also there are multiple optional attachments that can be used to increase the functional capabilities of the unit.

SPECIFICATION

| Technical Specifications | ||

|---|---|---|

| Model | NHL – 150 | |

| Output/Minute* | Up to 250 BPM | |

| Direction of Movement | Left to Right | |

| Output / Hour* | 3600 to 7200 | |

| Electric Specifications | Main Motor | 0.75 HP / 415 Volts / 50 Hz |

| Vacuum Pump | 0.5 HP / 415 Volts / 50 Hz | |

| Height of Conveyor | 860 ± 50 mm | |

| Change parts required | (A) Container: Feed Worm | |

| (B) Label: Label Muster, Upper – Lower Plates, Pusher Plate | ||

| Input Specifications | ||

|---|---|---|

| Label Specifications | Length | 20 mm to 140 mm |

| Width | 16 to 90 mm | |

| Thickness | 65 to 70 GSM (The Direction of Grains of the label must always be parallel to the containers axis. The paper should be flexible) | |

| Container Size | Round | ∅ 16 mm to ∅ 60 mm |

| Respective height : 40 mm to 120 mm | ||

SALIENT FEATURES

- Stainless Steel Cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion

- Adjustable Conveyor Height to align with other machines of the line

- ACVFD for speed control

- Very less time required in changing over from one size container / label to another

- Special self-aligning bearings ensure smooth and trouble free rotation of the components

- No container – No label mechanism avoids wastage of labels and also helps in keeping the unit neat & clean

- A highly efficient vacuum pump develops sufficient vacuum to hold any size of the label on the pick-up cylinder

- Equipped with Code over printing device and Digital Counter ( Optional )

- Flat bottles can be labeled on one surface with an attachment ( Optional )

- Bigger size of labels up to 165mm Length & 120 mm width can be handled with special design ( Optional )

For more details, Please click here.