Description

OVERVIEW

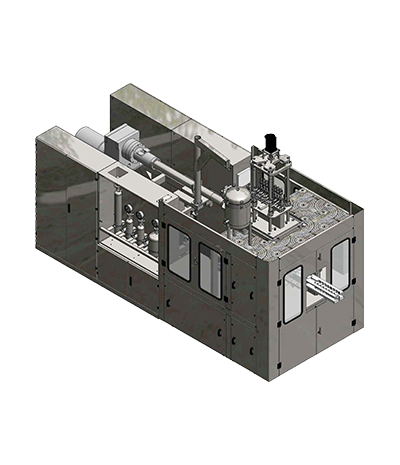

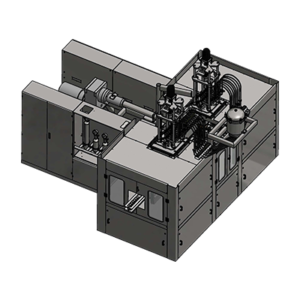

INJECTFILL 1S − SV20 / SV25 / SV30 is a fully integrated and automated system of blowing, aseptic filling and sealing to produce parenteral containers from plastic granules and filled them with sterile fluid product inside the mould in closed condition.

Standard description of the system:

The system is built with sturdy SS 304 pipe structure and having major functional components meticulously built inside or on the frame to make it a properly aseptic blow, fill and seal system. The entire system is an integrated mechanism of below functional areas.

- Plastic extrusion system with hopper and barrel

- Parison head

- TPD system with filling head

- Servo driven Mould station

- Multi cavity body and head mould

- Scrap separation system

- Exit conveyor

- Operation panel with HMI

- Electrical panel

- Pneumatic panel

- Hydraulic system with panel

- SIP system

- Laminar Air Flow over filling station

SPECIFICATION

| Standard design conditions | |

|---|---|

| Product to be filled | Sterile IV solutions |

| Plastic material | Basell Purell PE 3220D |

| Product temperature | Max 25 °C |

| Working area class | 100 |

| Standard machine configuration | |||

|---|---|---|---|

| Model | Cavities per mould | Max Fill Size | Output / Hour |

| INJECTFILL 1S – SV20 | 20 | 30 ml | 4800 |

| INJECTFILL 1S – SV25 | 25 | 20 ml | 6000 |

| INJECTFILL 1S – SV30 | 30 | 5 ml | 7200 |

| Standard Specifications | |||

|---|---|---|---|

| Model | INJECTFILL 1S – SV25 | INJECTFILL 1S – SV20 | INJECTFILL 1S – SV30 |

| No of Mould | 1 | ||

| No of Cavities | 25 | 20 | 30 |

| Size of Container | 20 ml with machine | 30 ml with machine | 5 ml with machine |

| Output/Hour | 6000 Ampoules | 4800 Ampoules | 7200 Ampoules |

| Extruder Details | |||

| Hopper Capacity | 50 Litre | ||

| MOC of Hopper | SS 316L | ||

| Extruder Screw ∅ | 70MM | ||

| Extruder Motor | Approx. 27 KW | ||

| Extruder Capacity | Up to 90Kg/Hr for suggested LDPE grade up to density 0.93 | ||

| MOC of Screw | EN grade with Nitride coating with 60-65 HRC | ||

| MOC of Barrel | EN grade with Nitride coating with 60-65 HRC | ||

| Parison Head | |||

| MOC of Parison Head | HSS P20 | ||

| Thickness control | Servo driven gap adjustment | ||

| Parison Cutting | Electric heated pneumatic knife | ||

| Blowing Mould | |||

| MOC of Mould Set | Aluminum Bronze | ||

| Mould Position Travel | By servo Motor | ||

| Mould Closing & Opening | By Hydraulic Pressure | ||

| Hydraulic Power Pack | |||

| Operative Pressure | Max. 100 bar. | ||

| Motor Capacity | 11 KW | ||

| Oil Reservoir | 225 Litre | ||

| Product Filling | |||

| Filling Principle | Time Pressure Dosing | ||

| Filling Accuracy | Up to 1% | ||

| Buffer tank capacity | 25 litre | ||

| Filling Nozzles MOC | SS 316L | ||

| Filling Range | 5ml to 20ml | 5ml to 30 ml | 0.5ml to 5ml |

| Vacuum System For Blowing | |||

| Pressure Generated | Up to (-) 0.9 bar | ||

| Vacuum Pump Capacity | 6 kW | ||

| Vacuum Tank Capacity | 25 litre | ||

| Process Air | In Client Scope | ||

| Pressure Require | Max 4 bar | ||

| Operational Air | In Client Scope | ||

| Pressure Require | 8 Bar | ||

| Quantity Require | 50 CFM | ||

| Cooling Water | In Client Scope | ||

| Temperature require | 10 – 16°C | ||

| Water Quantity Require | 3000 LPH for closed cycle circulation | ||

| Working pressure | Max 5 kg | ||

| Electric Power | |||

| 415V 3F + E + N | 71 kW | ||

| Steam for SIP | In Client Scope | ||

| Consumption | 40 kg / hour | ||

| Pressure | 2.5 bar | ||

| Net Weight | Approx. 9 ton | ||

For more details, Please click here.