Description

OVERVIEW

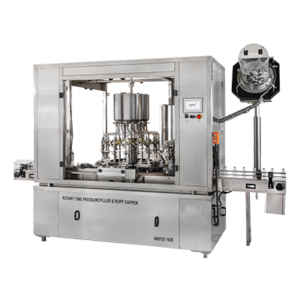

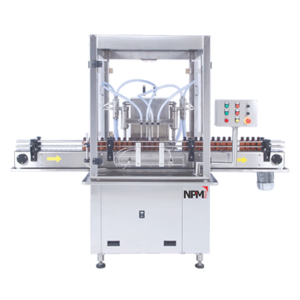

NPM’s Automatic Rotary Piston Filling Cum Sealing Machine is versatile, self-supported on stainless steel leg with a height-adjustable adjustment system. It is built on a sturdy welded MS frame completely enclosed in stainless steel sheets and doors for precision and quality work. The unit is made compact, versatile and is enclosed in stainless steel elegantly matt finish body to facilitate the servicing of the machine and its work on volumetric principle with rotary motion.

The machine moves its container on SS Slat conveyor and feeds the nozzles through feed worm & in-let star wheel. The filling station consist of a volumetric filling head and a central rotating liquid reservoir tank that continuously feeds the liquid by an external source. The automatic liquid sensor controls the liquid level through the reservoir tank with the help of a float switch and operates the solenoid valve. With the help of a screw, fill volume adjustment is customized for all syringes simultaneously.

SPECIFICATION

| Technical Specifications | |||||||

|---|---|---|---|---|---|---|---|

| Model | NRFS-4 / 4 | NRFS-6 / 6 | NRFS-8 / 8 | NRFS-12 / 8 | NRFS-16 / 8 | NRFS-20 / 10 | |

| Output / Hour* | 1500 to 6000 | 2500 to 7500 | 4000 to 9500 | 6000 to 11000 | 6000 to 13500 | 8000 to 16000 | |

| Number of Filling Heads / Syringe | 4 | 6 | 8 | 12 | 16 | 20 | |

| Number of Sealing Heads | 4 | 6 | 8 | 8 | 8 | 10 | |

| Direction of Movement | Left to Right | ||||||

| Fill Size | 30 ml to 250 ml | ||||||

| Electric Specifications | Main Drive | 3 HP / 415Volts / 50 Hz. | 5 HP / 415Volts / 50 Hz. | ||||

| Oriental Bowl | 0.25 HP / 415Volts / 50 Hz. | 0.5 HP / 415Volts / 50 Hz. | |||||

| Conveyor | 0.5 HP / 415 Volts / 50 Hz. | 0.75 HP / 415 Volts / 50 Hz. | |||||

| Height of Conveyor | 860 ± 50 mm | ||||||

| Change parts required | (A) Container: Star Wheel, Back Guide, Feed Worm, Nozzle | ||||||

| (B) Cap: Die, Delivery chute. | |||||||

| Input Specifications | ||

|---|---|---|

| ROPP Cap | Diameter | 22 mm to 28 mm |

| Height | 18 to 20 mm | |

| Container Size | Round | ∅ 28 mm to ∅ 60 mm |

| Respective Height : 60 mm to 120 mm | ||

| Flat / Square | Length : 30 mm to 70 mm | |

| Width : 20 mm to 50 mm | ||

| Height : 58 mm to 120 mm | ||

| Utility Requirement | ||

|---|---|---|

| Electric Supply | 3 Phase + Neutral + Earthing | |

| Electric Load | 3 kW | 5 kW |

| Air Consumption | 0.5 CFM @ 6 kg | |

SALIENT FEATURES

- GMP Model based on rotary piston filling concept for higher output

- Rigid MS structure with elegantly matt finished SS cladding

- Operational area is completely housed in SS frame and Acrylic enclosures

- Occupies less floor space and saves one operator as filling & sealing are combined

- Immediate sealing of filled bottles reduces the risk of contamination

- Accuracy ± 1% due to piston dozing principle

- Centralized volume adjustment system saves down time in volume setting

- No Bottle-No Fill system for every individual head ensures spillage free filling

- Sensors for adequate cap feeding save energy

- Electronic liquid level controller and pneumatic product in feed control valve

- Universal Coupling for quick and easy setting of In-feed worm

- In feed and/or out feed jam detection sensor(optional)

- Servo driven volume adjustment(optional)

- Inbuilt Pre Inspection (optional)

- Inbuilt Nitrogen flushing (optional)

- Motorized Height adjustment (optional)

- PLC based operations (optional)

- Cap loading elevator (optional)

For more details, Please click here.